Wire Rope Slings

We offer a complete selection of wire rope slings... mechanical splice, hand splice, multi-part braid and multiple leg with your choice of hardware.

When selecting the proper sling for your application, please allow our experienced staff to assist you in choosing the right type. It is vital for your efficiency, productivity and most of all your safety.

American Rigger’s Supply has always fabricated our wire rope slings with heavy duty, permanently attached sling tags.

O.S.H.A. and ASME B30.9 require that all wire rope slings be tagged with the name or trademark of the manufacturer, the rated capacity for specific configurations and the diameter or size of the sling. Under no circumstances shall a sling’s rated capacity be exceeded.

The user should maintain this identification so that it is legible during the life of the sling. All persons using the sling should read the tag and understand the information on it.

Advantages of wire rope slings:

- Steel construction resists abrasion and cutting

- Least expensive, by capacity, of all steel slings

- A wide variety of sling configurations and terminations

- Heat resistant to 400 degrees F

Two major characteristics of wire rope slings are flexibility and resistance to abrasion. In general, these traits are a direct function of the number of wires in the component wire rope. Fewer wires means larger diameter wires, with better abrasion resistance, better resistance to crushing and reduced flexibility. More wires result in decreased wire diameter, reduced resistance to abrasion and crushing but increased flexibility and kink resistance.

Two things to consider when using wire rope slings:

- Tests have shown that whenever a sling body is bent around a diameter, the strength of the sling is decreased. In order to maintain full basket capacity of a standard wire rope sling, one that is fabricated from 6X19 or 6X36 class wire rope, the diameter of the object being basketed must be 25 times the diameter of the sling rope. For smaller D/d ratios the basket capacity must be reduced. D/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling.

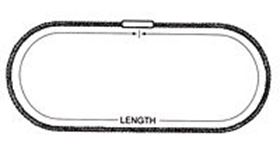

- For wire rope slings, damage and reduced strength can occur if the wrong size pin or hook is used. The width of the pin or hook should never exceed one half the inside length of the eye. If your pin or hook is large, request an oversized eye for the sling. Also, the diameter of the hardware used in the eye of a sling should be kept at least one size larger than the diameter of the wire rope. For instance, a minimum shackle size for a ½” sling would be 5/8”. Use a thimble in the eye of a sling for connecting small diameter hooks and hardware.

Please contact us for complete information regarding wire rope sling use and inspection. For inquiries and orders our experienced and friendly staff will be happy to hear from you.